Water softeners

Water hardness is a very important parameter for all technological uses of water, whether domestic or industrial.

Water is defined as “hard” when it has a high concentration of calcium and magnesium[1], which can be deposited, forming limescale.

In Italy, drinking water is supplied with widely varying hardness values, generally between 1 and 50°f but often above 25°f, meaning hard water with a high potential for the build-up of limescale[2].

Hardness values

Water classification

Presence in Italy

≤ 15°f

soft

20%

> 15 °f < 25

medium hardness

42%

≥ 25°f

hard

38%

Water is referred to as “softened” when it is treated with softeners that use special ion-exchange resins capable of reducing the concentration of calcium and magnesium salts, replacing them with sodium, that does not lead to limescale.

The benefits of softened water in the domestic setting can regard both drinking and sanitary water usage, representing 95% of all water consumption.

Regarding usage of drinking water, it is well known that hot drinks (such as tea and coffee) prepared with softened water have a better flavour, and the same applies to cooked food. “Hard” water does not generally represent a risk for human health, but it does represent a serious risk in the majority of technological uses, particularly those requiring heating of water.

In the domestic setting, the majority of water is used for purposes other than food and drink, and in all nearly all cases, limescale can lead to serious costs and compromised hygiene and sanitation.

High temperatures favour limescale deposits and this is why the surfaces most exposed to this phenomenon are those used in contact with hot water, such as heating elements in washing machines, dishwashers, irons and boilers, as well as pipes and taps. The layer of limescale that progressively accumulates on the surfaces of these systems reduces their efficiency and flow, compromising functionality over time.

Limescale also builds up with cold water, although more slowly, and it is not uncommon that drinking water pipes become partially or seriously blocked due to calcium carbonate deposits[3].

Limescale deposited on the metal surfaces of heating elements reduces the energy efficiency of these systems. The energy losses identified due to the build-up of limescale are the result of many tests, also conducted in collaboration with boiler manufacturers, which have faithfully reproduced the usage conditions of domestic hot water boilers, with and without appropriate water treatment.

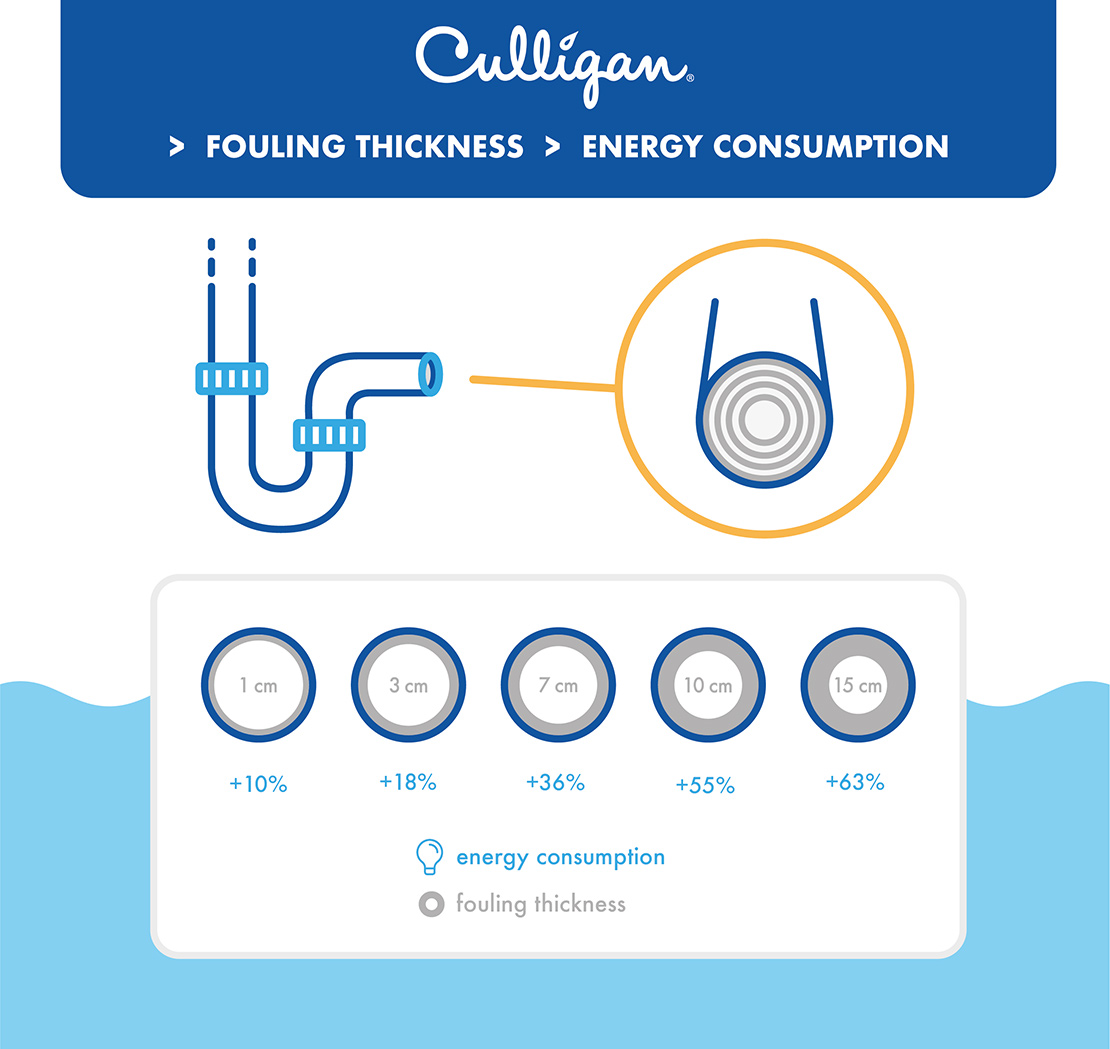

The thermal conductivity of limescale is around 100 times lower than that of iron, so limescale deposits have excellent insulating properties. Consider that a 1-mm-thick limescale deposit is capable of significantly reducing the heat-exchange capacity of a domestic hot water boiler, with a consequent 10% increase in energy consumption. As the thickness of limescale deposits increases, the heat-exchange efficiency decreases, meaning that energy consumption to achieve the same levels of service inevitably rises[4]. Furthermore, a significant increase in the thickness of limescale can lead to overheating of metal parts and their breakage due to thermal stress.

One method to evaluate energy loss involves measurement of the temperature of the fumes leaving the boiler, i.e. the thermal energy that is emitted into the atmosphere rather than used up to heat water.

Thickness of limescale (mm)

Increase in energy consumption (%)

1

10

3

18

7

36

10

55

15

63

In addition to energy losses, domestic hot water systems suffer other negative effects caused by limescale deposits:

- increased consumption and associated atmospheric CO2 emissions

- reduced useful life of systems

- lower hygiene conditions of systems, favouring bacterial growth (e.g. legionella grows far more easily in the presence of limescale deposits)

- drastic reduction in operating safety.

These factors are particularly significant in the case of boilers, which heat large volumes of water. It is important to remember that the build-up of limescale is cumulative, so even slightly hard water can significantly damage heating elements over time, and damage the boiler itself. This is the basis for the recent Standard UNI 8065/2019[5], outlining the adoption of a water treatment system for heating and domestic hot water production, according to the hardness of the water and the power of the boiler, as summarised in the table below:

Heating power (kW)

Water hardness (°f)

Treatment required

≤ 100

Any value

Upstream of the heating unit

- mechanical filter (>50µm)

- chemical conditioner regulator

Downstream of the heating unit

- sludge filter

- chemical conditioner

>100

≤ 15

Upstream of the heating unit

- mechanical filter (>50µm)

- chemical conditioner regulator

Downstream of the heating unit

- sludge filter

- chemical conditioner

>100

>15

Upstream of the heating unit

- mechanical filter (>50µm)

- softener

- chemical conditioner regulator

Downstream of the heating unit

- sludge filter

- chemical conditioner

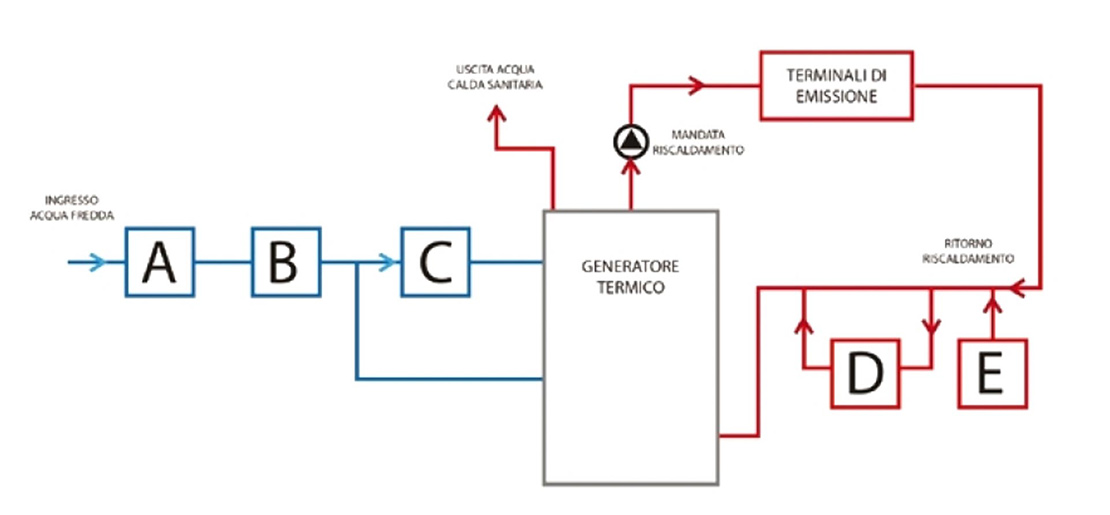

With installed heating power greater than 100 kW and in the presence of feed water with a hardness > 15°f, installation of a softener is mandatory, precisely to prevent inevitable technical problems due to the limescale deposits that would be encountered. The diagram below illustrates an example of an installation with combined production for heating and domestic hot water, with a heating power of > 100 kW and water hardness of > 15°f.

A = mechanical safety filter capable of > 50 µm filtration

B = softener

C = chemical conditioning to protect heating unit

D = sludge filter

E = chemical conditioning to protect heating circuit

Doses of conditioners in the water of domestic hot water systems must be regulated in proportion to flow rate. The amounts must be sufficient to achieve the desired effects without compromising drinking-water safety requirements.

Water treatment, which is mandatory for newly installed and refurbished systems, should be considered both for existing centralised systems and for independent systems with a nominal power up to 35 kW, and also for simple boilers for the production of domestic hot water alone.

Installation of a water softener allows a significant energy saving, as the absence of limescale in the pipes guaranteed by the softened water means that the hydraulic system offers better performance and uses less gas for heating water and rooms.

It is this energy efficiency that means installation of a softener, in the context of a building project for an individual residential unit or an entire apartment building, gives access to an Ecobonus and 50% tax deductibility on the purchase of the system and costs for associated work and any other professional services required.

[1] The most widespread unit of measurement for water hardness is French degrees (°f), where 1 °f = 10 mg/L calcium carbonate (CaCO3)

[2]“The quality of Italian drinking waters: hardness” Report EUR 18664 EN (1999)

[3] The diagram shows a cross-section of a drinking-water pipe (F = 15 cm) partially blocked by limescale

[4] “Quality and treatment of water in closed systems” Caleffi, 2012

[5] Italian Standard UNI 8065/2019 “Water treatment in systems for heating and air-conditioning, production of domestic hot water and solar thermal systems”

Uffici e ristoranti

Uffici e ristoranti Per la casa

Per la casa Piscine

Piscine