Culligan Water

for Food Industry

Cofeed, Algeria

We inform our kind customers that, from 1 April 2024, the services referred to on this web page will be provided by the company CWTS S.r.l. part of the Culligan group

Cofeed, Algeria

Cofeed is an Algerian company that contributes to the economic development of the country in the food industry. Cofeed has a seed crushing and oil extraction/refining/packing plant, equipped with advanced technology and a highly skilled staff.

They produce:

The instability of the inlet water required the treatment of drinking water and wastewater.

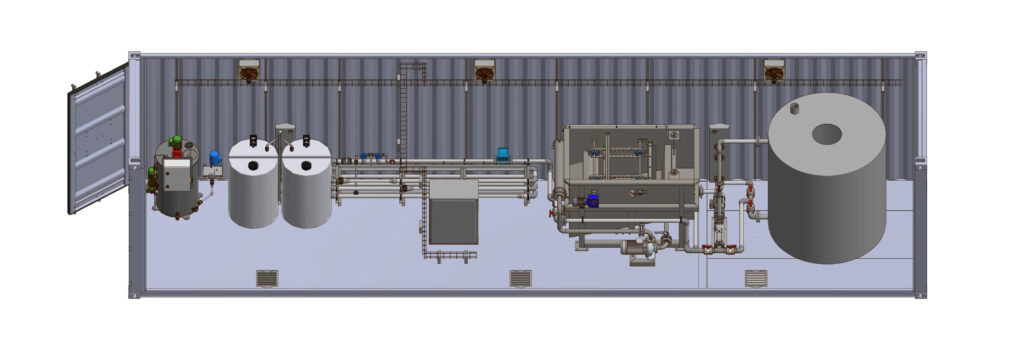

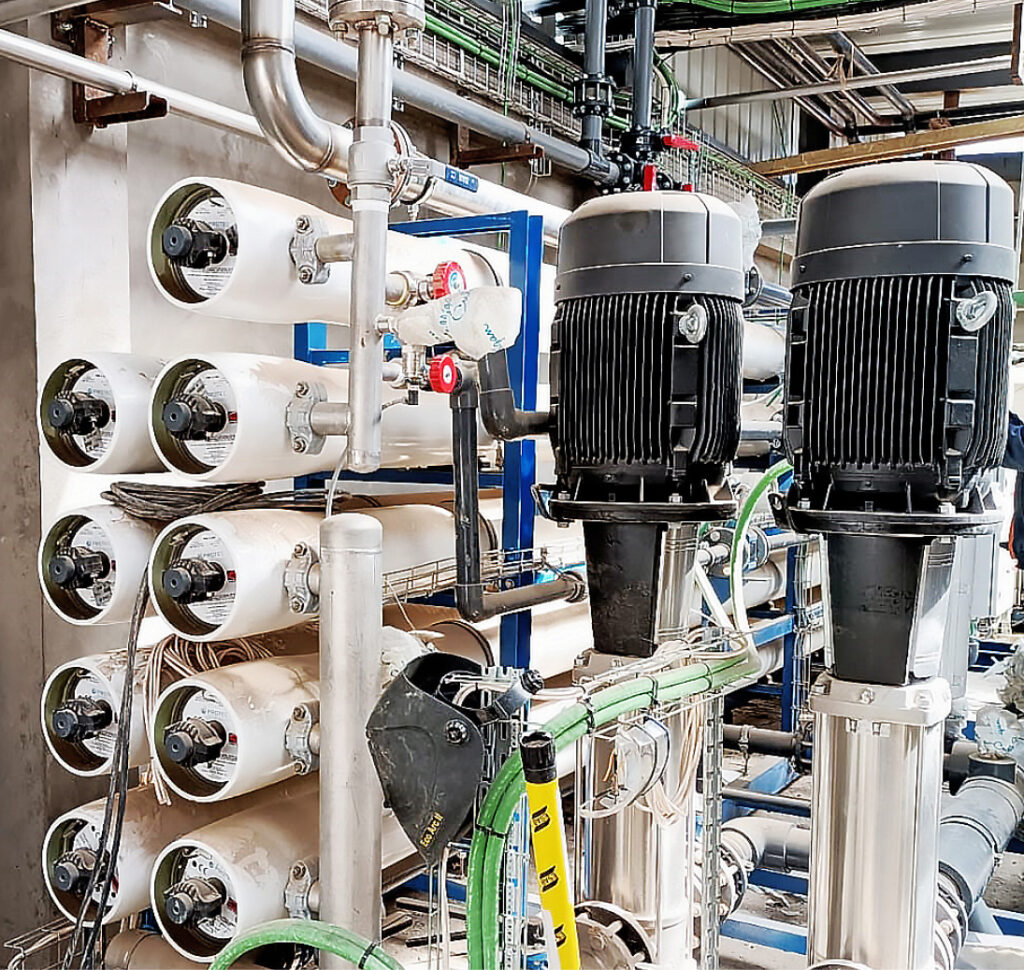

Culligan installed IW 53K SPECIAL EVO reverse osmosis system for a production of 53 m3/h at 75% recovery. The system is composed of 9 vessels with 6 membranes each for a total of 54 ESPA2 MAX membranes of 8×40”. The whole system is completely mounted on a carbon steel frame. Culligan’s proposed also a pre-treatment that includes: three HI-FLO 6 UF 84” multi-layer filters (flint-anthracite) filters, two operating in parallel and one in reserve, anti-scaling chemical dosing and chemical and sodium bisulfite. To be able to recover the excess water water from the cooling towers, Culligan installed three filters (2+1) immediately after the three HI-FLO 6 UR 84”. The entire system is completely mounted on a carbon steel frame and is controlled by an electrical power and control panel. In the water supply line for the cooling towers, a duplex decalcification system decalcification system with 750 liters of resin in each column has been designed to treat the water with a flow rate of 30 m3/h. An online hardness tester is integrated at the outlet.