A complete solution for

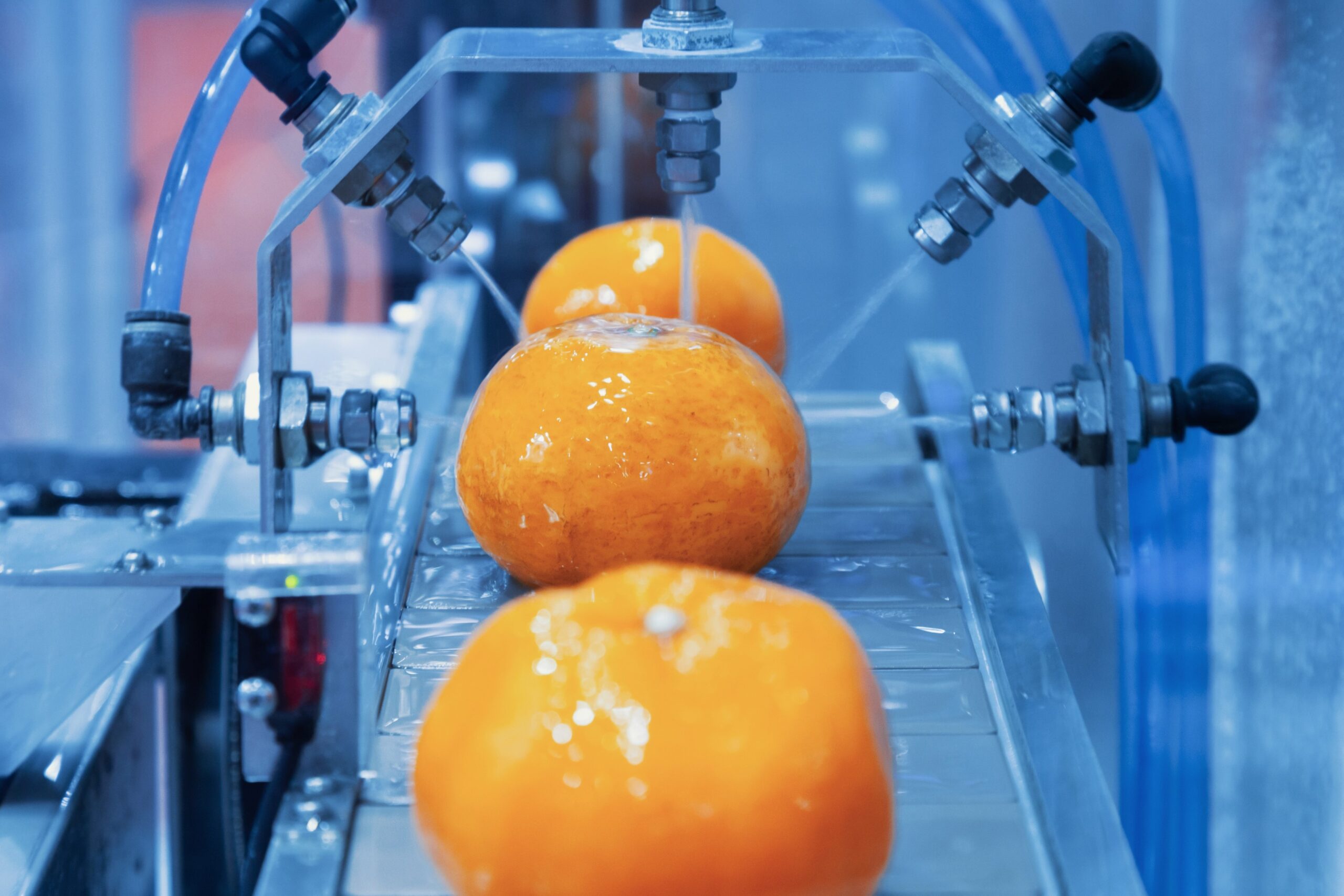

Water treatment applications for the agro-food industry

Water is crucial in all sectors of the food industry

We know how water often enters the production chain so we guarantee the highest quality standards. Research and development has made available intelligent anti-waste innovations that enable the recovery of water used in production processes, combining water saving and economy. These include the Water Filtering Station system from Culligan, a world leader in water treatment with over 80 years' experience and a cross-sector approach covering the entire water qualification chain.

Contact Culligan todayRaw water pre-treatment

Whatever type of industrial water you need and whatever raw water you use: well, river, lake, sea, reused effluent or drinking water, good pre-treatment is essential to protect your treatment plants and save considerably on costs.

Raw water often contains contaminants such as suspended solids, organic matter, ammonia, heavy metals such as manganese, iron and arsenic. All of these contaminants must be removed or reduced before introducing the water into your processes.

Culligan offers a complete range of raw water treatment technologies, including multilayer filters, ultrafiltration, reverse osmosis, chemical dosing and disinfection systems.

Improve efficiency with Culligan’s industrial reverse osmosis systems

Using the latest high-efficiency membrane technology, together with the quality of the materials used, Culligan can provide you with a fully pre-assembled RO system that is customised and quick to install. Culligan has decades of experience and thousands of RO installations worldwide. Learn more about Culligan’s reverse osmosis water systems.

The benefits of a Reverse Osmosis (RO) treatment system:

- Substantial cost savings

- Improved energy efficiency

- Enhancement of overall system performance

- Reduced limescale

- Superior taste and clarity

- Stain-free rinses

Applications Reverse Osmosis (RO) systems:

- Food and beverage production

- Pretreatment for boilers and cooling towers

- Pretreatment for high purity systems (EDI)

- Biopharmaceutical production

- Water jet cutting

- Humidification and steam generation

- Power generation

WFS, water and energy efficiency in one solution

Water Filtering Station (WFS) is the system designed by Culligan that is able to reuse the rejection water from the filling machines, recovering from 95% to 100% of the discharged water, equivalent to 22 million litres per year.

Water Filtering Station, developed over 3 years with 1 year of field testing, is the system that helps save large amounts of water and is designed to improve the future of the planet.

WFS is also capable of removing up to 100 ppm of oils and 10,000 ppm of hydrogen peroxide.

The plants, with different stages of filtration, mechanical and activated carbon, have an automatic control system capable of interfacing with the filling machines.

Reverse osmosis desalinator Culligan IW EVO

The Culligan IW EVO reverse osmosis desalinator, designed to treat high flow industrial water, is the ideal solution for the purification of fresh and brackish water.

Culligan IW EVO is the reverse osmosis desalinator for brackish water specifically designed to meet the demands of the most demanding industrial and municipal applications.

The use of the most advanced reverse osmosis membrane technology guarantees the removal of over 99% of contaminants, including dissolved minerals, bacteria, particulates and other impurities, producing high purity water suitable for demanding applications such as boiler feed.

TOTAL FLEXIBILITY – the use of a modular platform approach allows a full range of pre-engineered options to be selected and added to the basic IW Evo unit, enabling users to quickly identify the unit that perfectly meets their specific needs.

Learn more on the dedicated page.

Uffici e ristoranti

Uffici e ristoranti Per la casa

Per la casa Piscine

Piscine