Water treatment

Water treatment plants and global solutions for industry

Culligan designs, engineers and manufactures water treatment plants for the industrial sector: global solutions tailored to each specific need, from primary water treatment systems to wastewater treatment.

Water is a crucial element in all industrial sectors.

Its quality affects most processes, with a huge impact on the water treatment plants themselves, on operating costs and on the environment.

Culligan – a leading company in water treatment with 85 years of experience – is able to offer global solutions and specific water treatment plants for each sector, which allow to reduce the costs of processes and machinery that use water, with an after-sales service. highly reliable and professional sale.

Culligan’s water treatment solutions and plants cover a wide range of industries: food, bio-pharmaceutical, commercial, energy, manufacturing, military, municipal, naval, hospital and healthcare, offshore oil and gas, tourism and hospitality petrochemicals.

Solutions defined as “global” because they include the design, installation and commissioning of water treatment plants, revamping, routine maintenance and supply of suitable chemical products, with customized multi-year contracts and long-term assistance..

Whatever the type of application and water used – well, river, lake, sea wastewater – Culligan has the specific treatment solution, from water purification and potabilization plants for the municipal, to treatment for civil and industrial uses, up to systems mobile and containerized water purification systems.

Industrial Water Treatment Applications Raw Water Pre-Treatment

Wherever your raw water comes from: well, borehole, surface water, river water, sea water, recycled waste streams or potable water from the municipal supply, good pre-treatment is essential to protect your downstream processes and save costs.

Raw water often contains a wide range of water contaminants such as suspended solids, organics, hardness, heavy metals such as manganese, iron, lead and arsenic. All of which must be removed or reduced before introducing the water into your processes. Culligan offers a number of technologies designed specifically to treat raw rater including media filtration, ultrafiltration, reverse osmosis, chemical dosing and disinfection systems.

Process water treatment systems

Thanks to the process water treatment systems, it is possible to recover the water used, treat it according to the highest standards, and reintroduce it into the production water system, reducing: water impact, consumption and energy costs, while protecting the environment.

Culligan systems can be fully integrated into production processes and can be interfaced with control systems, to ensure water that meets the specific quality standards for any process.

Pre-assembled water treatment systems

Culligan also offers complete solutions for water treatment on specific requests, installed at the customer’s on skids and containers that reduce installation and start-up times.

Water treatment systems for technological use

For the water treatment of boiler and cooling plants, Culligan offers specific and customized solutions that minimize investment and management costs, consumption of water, electricity and fuel, and a complete supply of treatment plants, chemicals and technical assistance.

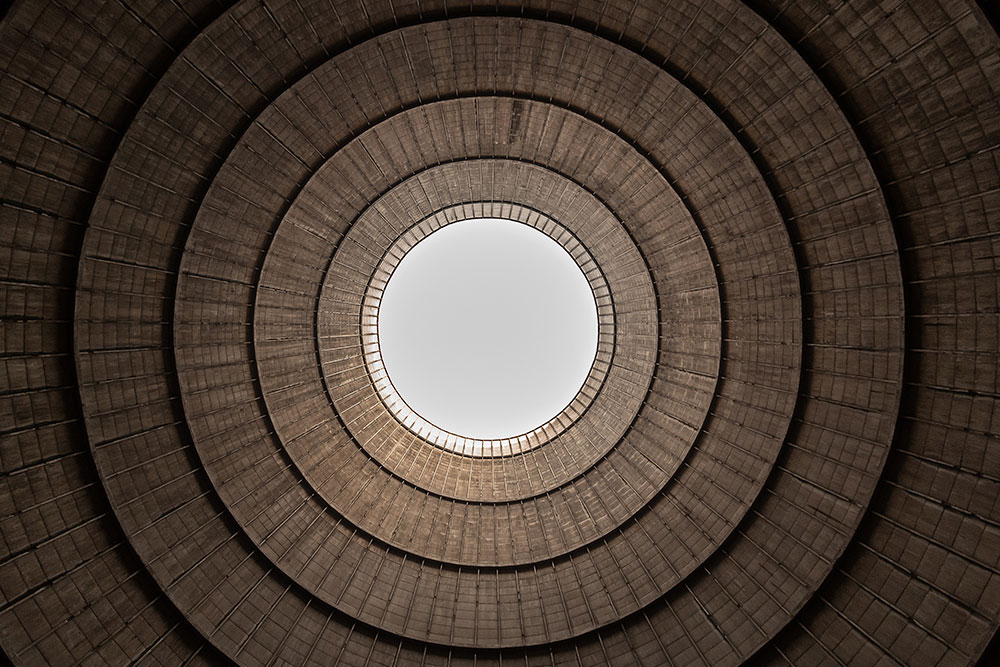

Cooling water treatment

Cooling water is an integral part of many industrial processes.

If a cooling system has malfunctions or critical passages, it negatively impacts the entire production system.

Culligan offers specific and customized solutions for both make-up water and waste water, which make it possible to: reduce the use of water and energy; prevent the formation of scale, deposits and corrosion in heat exchangers by minimizing the risk of unexpected interruptions; and to safely manage biological development control and Legionella responsibilities.

Boiler water treatment

Then there are systems dedicated to the treatment of the make-up water of steam generators and to the recovery of condensate water, including softening and reverse osmosis systems for low and medium pressure boilers, and demineralization and electro-deionization systems for high pressure boilers. high pressure.

Systems that allow to prevent malfunctions and unexpected interruptions caused by corrosion phenomena; to prevent the accumulation of encrustations and deposits; ensure the efficiency of the heat exchange surfaces; control drains and reduce the environmental impact with considerable advantages:

- energy saving

- reduction of chemical conditioning

- reduction of costs and consumption of energy, water and fuel

Wastewater treatment and waste water purification

Culligan also offers a range of compact and low-cost wastewater treatment systems, ideal for the treatment and purification of wastewater from industrial and civil processes: Dosing and analysis systems, Biological and chemical-physical purifiers, Filtration and Ultrafiltration, MBR.

Complete solutions for the entire water treatment cycle in the industrial sector, which allow water to be recovered, recycled and reused, reducing consumption and operating costs. Mobile solutions for containerized wastewater with MBR system (Membrane BioReactor) are also available.

Water Applications on Cruise Ships

Cruise ships need all-purpose ship water treatment systems. From fresh drinking water to swimming pools, from whirlpools to water for services.

Over 20 years experience in water treatment for marine and cruise ships,

Culligan supplies water treatment systems that are now the byword for reliability, safety, and above all clean, pure water.

Today Culligan is the preferred supplier for water treatment equipment on many of the most prestigious cruise lines around the world.

Uffici e ristoranti

Uffici e ristoranti Per la casa

Per la casa Piscine

Piscine