ULTRAFILTRATION (ULF)

Filtration

Filtration of water contaminated by micro-pollutants, bacterial load and suspended solids.

Pretreatment

Pretreatment for Reverse Osmosis plants, to always guarantee the quality of the feed water for protection of the membranes (SDI<3).

Potobilization

Production of drinking water from surface, spring or well water for industries, municipal waterworks, residential areas, hotels, recreational centers and apartment blocks, etc.

Reuse of Waste Water

Tertiary filtration in wastewater treatment plants to obtain quality water suitable for reuse in non-potable utilities.

Advantages of ULF systems

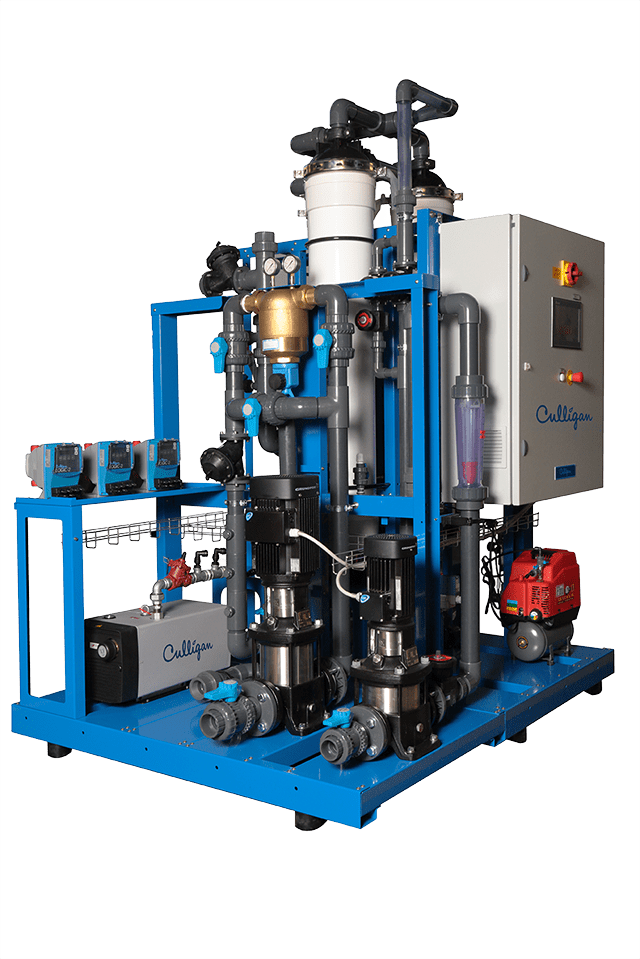

- All the possible configurations are pre-assembled on skids and interconnected with each other.

- Extremely flexible thanks to a complete range of options.

- Suitable for use with well water and with surface water and with turbidity up to 300 NTU.

- Recovery rates up to 98.5%.

- Effective technical assistance thanks to maximum accessibility of parts and after-sales service worldwide.

- Made in Italy and fully compliant with CE standards.

SOLUTIONS AND CONFIGURATIONS

- Self-cleaning or basket filter, at inlet, with degree of filtration 110 μm as membrane protection.

- Vertical multistage centrifugal feed and backwash pump in stainless steel.

- CEB vertical multistage centrifugal wash pump in stainless steel.

- Metering pumps for correct dosing the chemicals needed during the washing and disinfection phases.

- Cross flow mode to also treat water loaded with turbidity values up to 300 NTU.

- Air backwashing system equipped with vane compressor or side channel blower.

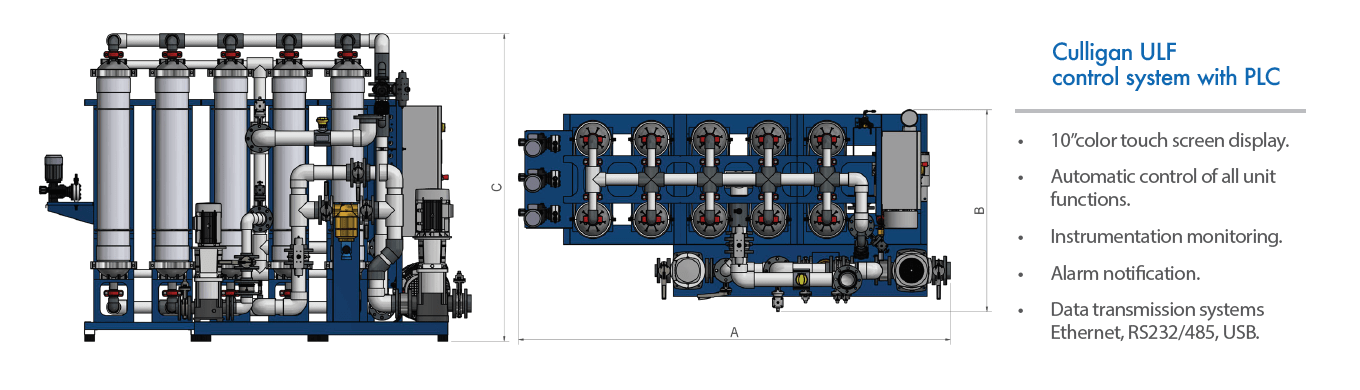

- PLC electric control panel with dedicated software pre-assembled on the frame; alternatively the unit can be arranged to be managed by an external PLC.

Uffici e ristoranti

Uffici e ristoranti Per la casa

Per la casa Piscine

Piscine